Aeration Systems

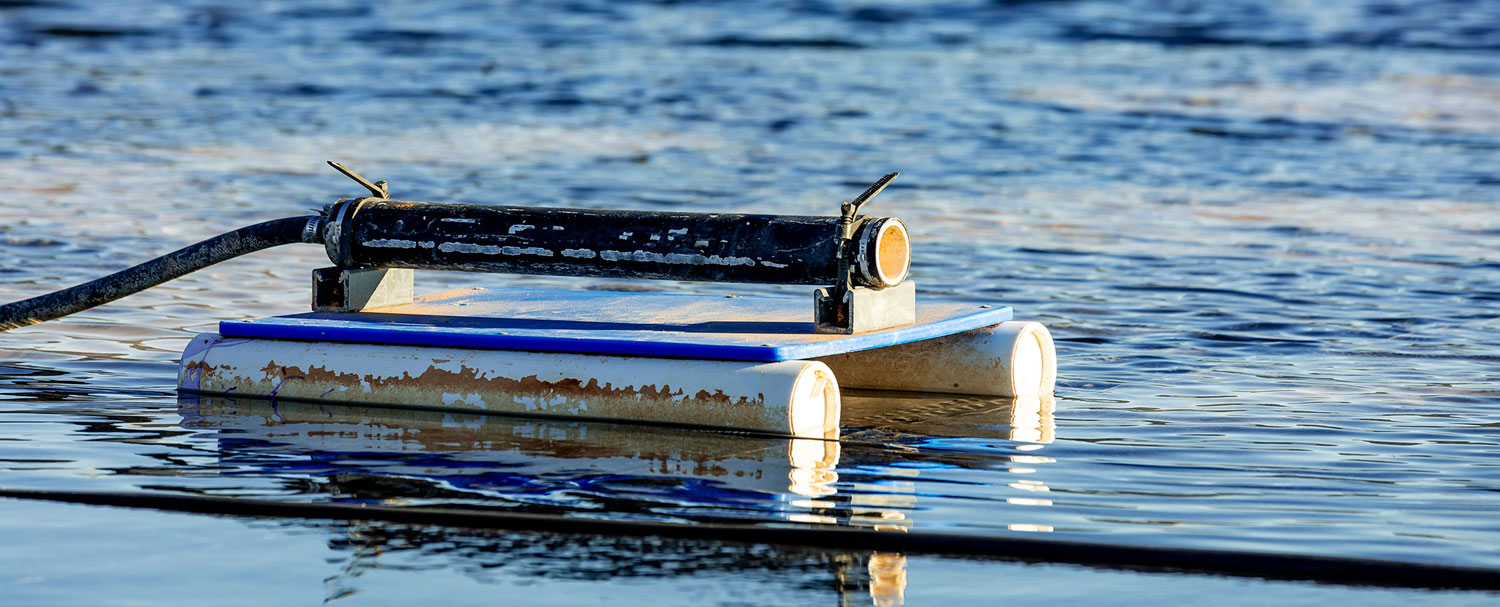

Whether an operator is using fresh or produced water, treating bacteria in the water is a crucial part of the process. A quality aeration system can substantially improve the quality of the water in a frac pit, which is why Big D installs aeration systems in produced water frac pits that mix and aerate the water in a cost-effective way. Our aeration systems consist of a combination of air diffusers, hoses, and an air compressor. A single system (one compressor cabinet and 4 air pod diffusers) can aerate up to a 8-acre portion of a pond, depending upon air diffuser placement, nutrient concentrations, biological oxygen demand, water depth, and other physical characteristics of the water.

Aeration Benefits:

- Increase Dissolved Oxygen Concentrations

- Increase Water Clarity

- Reduce Algal Blooms

- Reduce High Metal Concentrations

- Reduce Nutrient Releases by Anoxic Sediments

- Reduce Buildup of Gases

- Reduce Release of Noxious Odors

- Reduce the Accumulation of Sediments

Our aeration systems use billions of micron sized bubbles to improve pond quality. The system is powered by two 1/3 H.P. energy efficient, dual piston air compressors which can deliver air under high pressures in water depths up to 35 feet. The systems operate very quietly and efficiently. The compressed air is delivered to the air pods using self-weighted tubing, which is kink proof and puncture resistant. The air pod diffusers contain a self-cleaning 24-inch EPDM flexible membrane tube diffuser equipped with a triple check valve system. The check valve system is to prevent water and sediment from flowing back into the air supply lines during system shut down.

The aeration systems are installed by Big D and can be customized for any pond size and locations with multiple pond cells. It is best practice to install the aeration system at the time of liner installation.

© Copyright 2025 BigD Companies. All Rights Reserved. | Privacy Policy