Liner Systems

Liner Systems

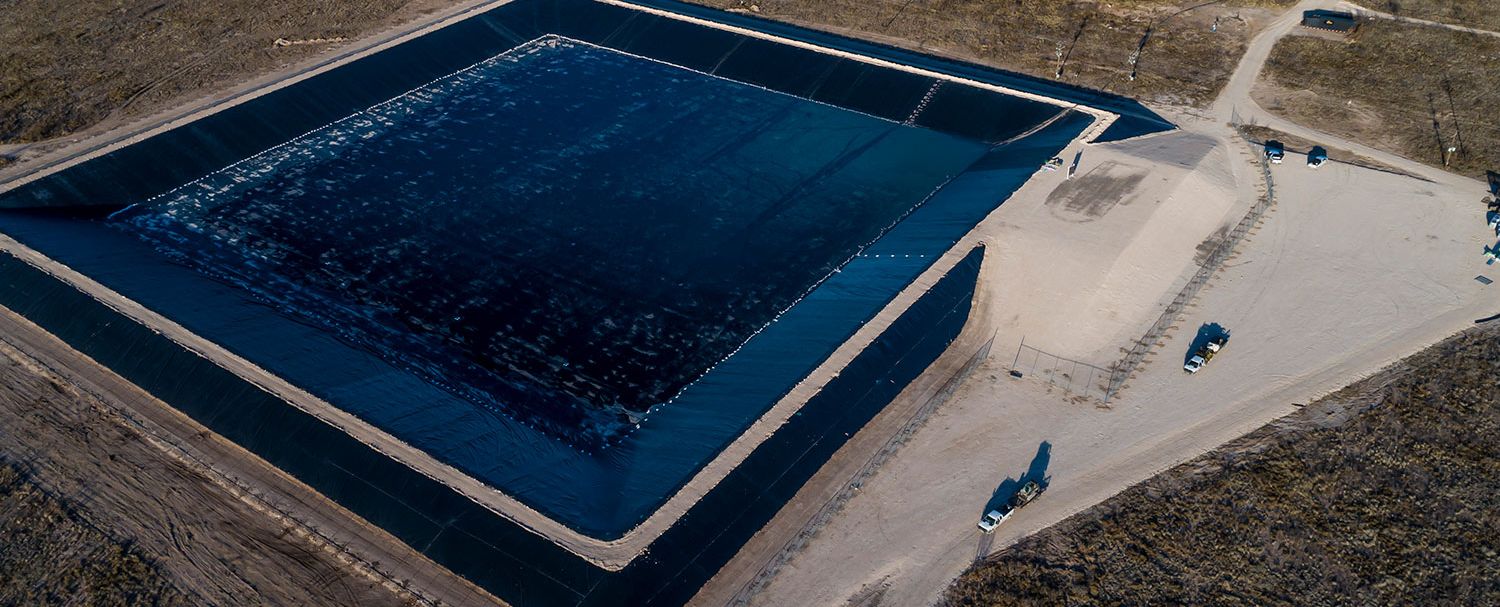

Big D Equipment offers extensive experience and expertise in pit lining systems. We currently employ more than 40 experts who specialize in liner installations that range from 6 mil to 100 mil. Several of our pit liners are certified geomembrane technicians and are also certified as Master Seamers. We've served the oil field and waste management industry for over 40 years, with our team representing more than 350 years of combined experience in the pit-lining industry. Our pit liners mobilize daily to perform pit lining services for drilling pits, frac pits, deep buries, and secondary containments.

Big D primarily focuses on serving oil fields in the Permian Basin region of Texas and southeast New Mexico, but we are also capable of designing and installing permanent pond liners for customers around the country.

Drilling / Reserve Pits

No matter the size, shape, or depth, Big D has the experience and inventory necessary to install a liner perfectly suited for your application. Many of the pit-lining projects we complete include single horseshoe, double horseshoe, and workover pits used for drilling and completion operations.

Fresh Water Frac Pits

As the oilfield continues to expand, pit volumes and the volume of water required to support horizontal fracking continues to expand. Currently, operators most often use 30 mil, 40 mil, and 60 mil high-density polyethylene liners, but the most appropriate liner for your project is determined by a number of variables, including the required life expectancy and volume of the pond. Operators depend on our recommendations for the liner that will best fulfill their project’s needs and that will withstand the harsh environmental conditions of West Texas.

For both vertical and horizontal drilling and completion programs, Big D offers the crews and experience to line pits of any volume for any operation.

At the core of our liner program is a dedicated focus on quality control. With all our experience, we still see the importance of providing onsite quality control on every major job. Big D Equipment provides our own in-house quality control personnel on every major geomembrane installation. Our quality control personnel will make all the necessary documentations and oversee daily testing of material and installation.

Produced Water Storage Pits

With many operators moving to horizontal drilling and hydraulic fracturing, the demand for water is constantly increasing. Many operators in the Permian Basin are using produced water to supplement other sources. Doing so requires compliance with a number of environmental mandates, making Big D’s expertise in lining systems that conform to both Texas and New Mexico regulations an invaluable resource. We have more experience at installing double-lined storage pits with leak detection systems than any of our competitors.

Texas Railroad Commission Requirements for Produced Water Frac Pits

The Texas Railroad Commission (RRC) requires that frac pits conform to a number of significant standards. Our construction standards are fully aligned with RRC regulations.

RRC’s basic requirements for produced water frac pits:

• Adequate freeboard, minimum of 2’

• Compaction of subgrade, built-in lifts

• Free of rocks, debris, or irregularities with sharp edges

• Top width of dike: minimum of 4 feet, though we recommend 12 feet

• Side slopes not steeper than 3 to 1 grade

• Dikes (walls) are keyed into underlying soil

• Lined with liner providing hydraulic conductivity 1.0 x 10-7 cm/s or less. (Minimum of 30 mil is best practice)

• Liner seams should be oriented up and down, not across slopes

• Pits must be emptied and inspected annually, OR be constructed with double liners and undergo Monthly Leak Detection Monitoring

At the core of our liner program is our vast experience in quality control. Through our experience, we recognize the importance of providing onsite quality control on every major job, which is why Big D Equipment provides quality control personnel on every major geomembrane installation. Additionally, we make all the necessary documentations and oversee daily testing of material and installation.

Deep Bury Pits

During the remediation process, landowners often request that a liner be used prior to burying the solids and mud remaining from the drilling process. Many of the resulting holes may be as deep as 20 feet, which can present difficulties in lining the pit. Big D’s crews have the experience and know-how to safely install 6 to 20 mil reinforced liners for this application.

Secondary Containment

econdary containments prevent hazardous liquids from spilling and contaminating soil and water, making them necessary for tank battery sites, saltwater disposal wells, gas processing facilities, and salt mines. Small containments are also frequently needed for fuel storage, pump containments, and short term frac tank storage. At Big D, we combine 20, 30, 40, or 60 ml liners with highly skilled extrusion welders to seal secondary containment sites, effectively preventing long-term leakage and contamination. This can be seen as a specialty installation, as many secondary containments have multiple pipe systems that require leak-proof boots.

- Turnkey Frac Services

- Turnkey Drill Site

- Construction Company

- Equipment Company

For More Information on Big D Pit Lining Contact Us Now

Justin Primera - 432.967.5925

© Copyright 2025 BigD Companies. All Rights Reserved. | Privacy Policy